Obere oghere ọkụ Graphite Electrode maka ọkụ ọkụ eletrik maka ụlọ ọrụ igwe na ebe a na-emepụta ihe

Nka nka

Chart 1: Nka nka Maka Obere Okirikiri Graphite Electrode

| Dayameta | Akụkụ | Nguzogide | Ike Flexural | Modul na-eto eto | Njupụta | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chart 2: Ikike ibu ugbu a maka Obere dayameta Graphite Electrode

| Dayameta | Ibu dị ugbu a | Njupụta dị ugbu a | Dayameta | Ibu dị ugbu a | Njupụta dị ugbu a | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chart 3: Ogo Electrode Graphite & Nkwenye Maka Obere Dayameta Graphite Electrode

| Ọnụ ala dayameta | Oke dayameta (mm) | Ogologo aha aha | Ndidi | |||

| Inch | mm | Oke. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75-50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75-50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Ngwa isi

- Calcium carbide na-agbaze

- Mmepụta Carborund

- Nnụcha corundum

- Ọla na-adịghị ahụkebe na-agbaze

- Ferrosilicon osisi refractory

Ntuziaka ntuziaka na iji maka Graphite Electrodes

1.Wepụ ihe mkpuchi nchebe nke oghere electrode ọhụrụ ahụ, lelee ma eriri dị na oghere electrode zuru ezu na eriri ahụ ezughị ezu, kpọtụrụ ndị ọkachamara ọkachamara iji chọpụta ma enwere ike iji electrode;

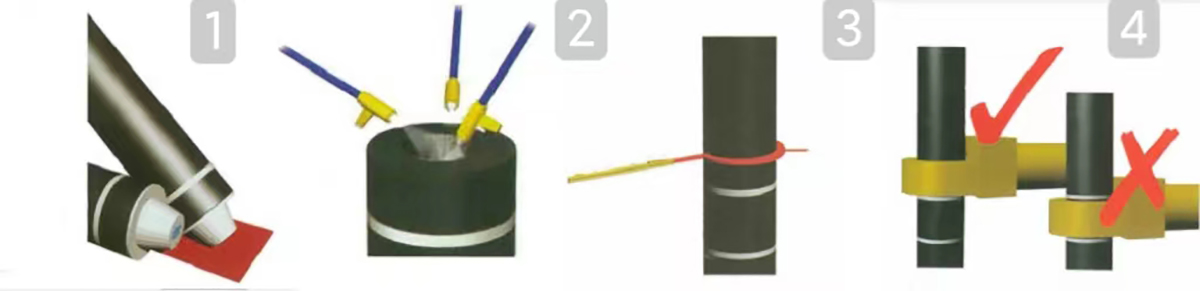

2.Tinye ihe nkwụnye electrode n'ime oghere electrode n'otu nsọtụ, ma tinyekwa ihe ntanye dị nro n'okpuru nsọtụ nke ọzọ nke electrode ka ọ ghara imebi njikọ electrode; (lee pic1)

3. Jiri ikuku abịakọrọ na-afụ uzuzu na sundries n'elu na oghere nke njikọ electrode, wee hichaa elu na njikọ nke ọhụrụ electrode, hichaa ya na brush; (lee pic2)

4.Welie ọhụrụ electrode n'elu na-echere electrode ka kwekọọ na electrode oghere na-ada nwayọọ nwayọọ;

5. Jiri uru torque kwesịrị ekwesị iji kpọchie electrode nke ọma; (lee pic3)

6.Ekwesịrị idowe ihe njide n'ahịrị mkpu.(lee pic4)

7.In the refining period, ọ dị mfe ime ka electrode dị nro ma mee ka agbaji, nkwonkwo daa, mụbaa oriri electrode, biko ejila electrodes bulie ọdịnaya carbon.

8.Due na ihe dị iche iche nke ndị na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe, ihe anụ ahụ na nke kemịkal nke electrodes na nkwonkwo nke onye ọ bụla na-emepụta ihe. Ya mere, a na-eji ya, n'okpuru ọnọdụ izugbe, biko agwakọtala electrodes na nkwonkwo nke ndị nrụpụta dị iche iche mepụtara.