Igwe ọkụ dị njupụta dị elu dị elu maka igwe ọkụ na-agbawa ọkụ na-agbaze nchara nchara.

Nka nka

Chart 1: Nka nka Maka Obere Okirikiri Graphite Electrode

| Dayameta | Akụkụ | Nguzogide | Ike Flexural | Modul na-eto eto | Njupụta | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ọnụ ara | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chart 2: Ikike ibu ugbu a maka Obere dayameta Graphite Electrode

| Dayameta | Ibu dị ugbu a | Njupụta dị ugbu a | Dayameta | Ibu dị ugbu a | Njupụta dị ugbu a | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chart 3: Ogo Electrode Graphite & Nkwenye Maka Obere Dayameta Graphite Electrode

| Ọnụ ala dayameta | Oke dayameta (mm) | Ogologo aha aha | Ndidi | |||

| Inch | mm | Oke. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75-50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75-50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Ngwa isi

- Calcium carbide na-agbaze

- Mmepụta Carborund

- Nnụcha corundum

- Ọla na-adịghị ahụkebe na-agbaze

- Ferrosilicon osisi refractory

Ntuziaka ntuziaka na iji maka Graphite Electrodes

1.Jiri ngwá ọrụ ebuli pụrụ iche na ndụ graphite electrode zere mebiri emebi n'oge njem.(lee pic1)

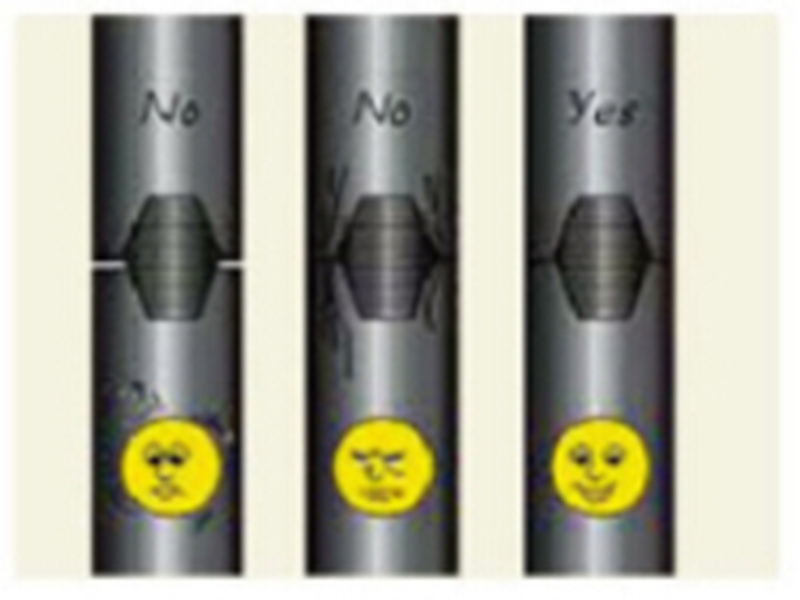

2.Graphite electrode ga-emerịrị ka mmiri na-ezo ma ọ bụ na-agba mmiri, snow, debe ya ka ọ kpọọ nkụ.(lee pic2)

3. Jiri nlezianya nyochaa tupu eji ya hụ na oghere na eriri ara dị mma maka ojiji, gụnyere nyocha maka pitch, plug.(lee pic3)

4.Sachaa eriri ara na sọket site n'ikuku mkpakọ.(lee pic4)

5.Before were, the graphite electrode must be Fikiere n'ime ọkụ, na ihicha okpomọkụ kwesịrị ịbụ ihe na-erughị 150 ℃, oge a mịrị amị kwesịrị ịbụ ihe karịrị 30hours. (lee pic5)

6.Graphite electrode ga-jikọọ tightly na ozugbo na adabara tightening torque.(lee pic6)

7.To zere graphite electrode breakage,tinye nnukwu akụkụ na ala ọnọdụ na obere akụkụ na elu ọnọdụ.